Lincoln Corsair: Engine - 2.0L EcoBoost (177kW/240PS) – MI4 / Removal and Installation - Oil Pump

Special Tool(s) / General Equipment

|

100-002

(TOOL-4201-C)

Holding Fixture with Dial Indicator Gauge |

|

303-1685 Alignment Tool, Camshaft |

|

303-1688 Preload Tool, Balance Shaft |

|

303-507 Timing Peg, Crankshaft TDC TKIT-2001N-FLM TKIT-2001N-ROW |

Removal

-

Remove the oil pan.

Refer to: Oil Pan (303-01A Engine - 2.0L EcoBoost (177kW/240PS) – MI4, Removal and Installation).

-

Mark the balancer unit and shafts on the top for reference that the balancer unit is at TDC .

|

-

Remove the bolts and the oil screen and pickup tube.

|

-

Remove and discard the oil screen and pickup tube O-ring seal.

|

-

Remove the bolts and the oil outlet tube.

|

-

Inspect the oil outlet tube O-ring seal and replace if damaged.

|

-

-

Remove the oil inlet tube-to-bracket bolt.

-

Remove the bolt and the oil inlet tube bracket.

-

Remove the bolts and the oil inlet tube.

-

Remove the oil inlet tube-to-bracket bolt.

|

-

Inspect the oil inlet tube O-ring seal and replace if damaged.

|

-

NOTE: Due to the precision interior construction of the balancer unit, it should not be disassembled.

Remove the bolts and the balance unit.

|

-

Remove the adjustment shims from the seat faces of the balancer unit.

|

Installation

-

Prime the oil pump. Add 2 tablespoons of clean engine oil to the oil pump and rotate the oil pump by hand.

Refer to: Specifications (303-01A Engine - 2.0L EcoBoost (177kW/240PS) – MI4, Specifications).

-

Install the master adjustment shims (No. 50) on the seat faces of the balancer unit.

|

-

With the balancer unit shaft marks at the TDC

position, slowly install the balancer unit to the cylinder block to

avoid interference between the crankshaft drive gear and the balancer

unit driven gear.

|

-

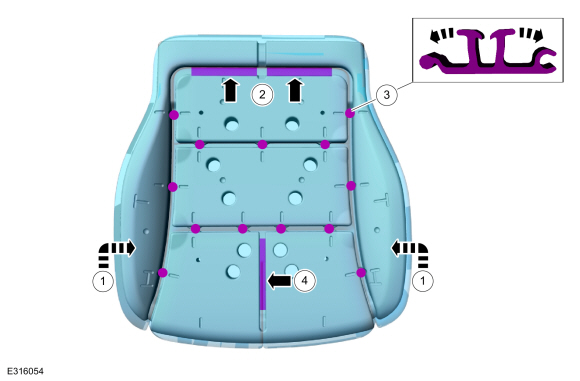

Install the bolts and tighten in sequence shown.

Torque:

Stage 1: 27 lb.ft (36 Nm)

Stage 2: 60°

|

-

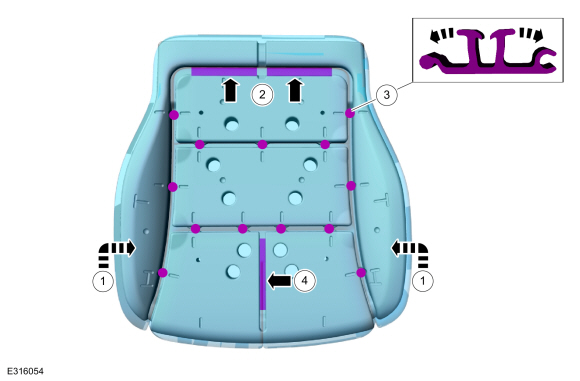

Loosen the bolts.

|

-

Tighten the bolts in sequence shown.

Torque:

Stage 1: 133 lb.in (15 Nm)

Stage 2: 45°

|

- Remove Special Service Tool: 303-507 Timing Peg, Crankshaft TDC.

|

-

NOTE: Once the special tool is removed the valves will go into a neutral position and crankshaft and pistons can now freely be rotated.

Remove Special Service Tool: 303-1685 Alignment Tool, Camshaft.

|

-

NOTICE: Do not remove the spark plugs when the engine is hot or cold soaked. Spark plug thread or cylinder head damage can occur. Make sure that the engine is warm (hand touch after cooling down) prior to spark plug removal.

NOTICE: If a spark plug is dropped, internal damage may result and the spark plug must be discarded. The use of a damaged spark plug may cause cylinder misfire resulting in engine damage.

-

Use compressed air to remove any foreign material in the spark plug well before removing the spark plugs.

-

Remove the spark plugs.

-

Use compressed air to remove any foreign material in the spark plug well before removing the spark plugs.

|

-

Install the crankshaft pulley bolt and rotate the

crankshaft to confirm that there are no meshing problems between the

balancer unit gear and the crankshaft gear.

|

-

Install the special tool and rotate the crankshaft

slowly clockwise until the crankshaft balance weight is up against the

Crankshaft TDC Timing Peg. The engine is now at TDC .

Use Special Service Tool: 303-507 Timing Peg, Crankshaft TDC.

|

- Remove Special Service Tool: 303-507 Timing Peg, Crankshaft TDC.

|

-

NOTE: Measure the backlash and verify that it is within specified range at all of the following 6 positions: 10 degrees, 30 degrees, 100 degrees, 190 degrees, 210 degrees and 280 degrees. It will be necessary to reset the measuring equipment between measurements.

NOTE: The measurement must be taken with the Dial Indicator Gauge with Holding Fixture, a 5-mm Allen wrench and worm clamp set up as shown. Mark the Allen wrench with a file 20 mm (0.79 in) above the driven gear top surface. Make sure the worm clamp and Allen wrench are not touching the balance shaft housing.

-

NOTE: Make sure the worm clamp and Allen wrench are not touching the balance shaft housing.

Install the 5-mm Allen wrench and tighten worm clamp as shown.

-

Mark the Allen wrench with a file 20 mm (0.79 in) above the driven gear top surface.

-

Install the balance shaft preload tool and bolts as shown.

Use Special Service Tool: 303-1688 Preload Tool, Balance Shaft.

-

Install and position the dial indicator gauge with

holding fixture on the Allen wrench 20 mm (0.79 in) as shown.

Use Special Service Tool: 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge.

-

Rotate the crankshaft clockwise and measure the

backlash at all of the following 6 positions: 10 degrees, 30 degrees,

100 degrees, 190 degrees, 210 degrees and 280 degrees.

-

|

-

Using the backlash measurement, select the proper shims from the Adjustment Shim Selection Table.

-

Backlash

-

Selection shim (No.)

-

Shim thickness

-

Backlash

|

-

Remove the bolts and the balance unit.

|

-

Remove the master adjustment shims (No. 50) from the balancer unit.

|

-

Install the selected adjustment shims on the seat faces of the balancer unit.

|

-

Install the special tool and rotate the crankshaft

slowly clockwise until the crankshaft balance weight is up against the

Crankshaft TDC Timing Peg. The engine is now at TDC .

Use Special Service Tool: 303-507 Timing Peg, Crankshaft TDC.

|

-

With the balancer unit shaft marks at the TDC

position, slowly install the balancer unit to the cylinder block to

avoid interference between the crankshaft drive gear and the balancer

unit driven gear.

|

-

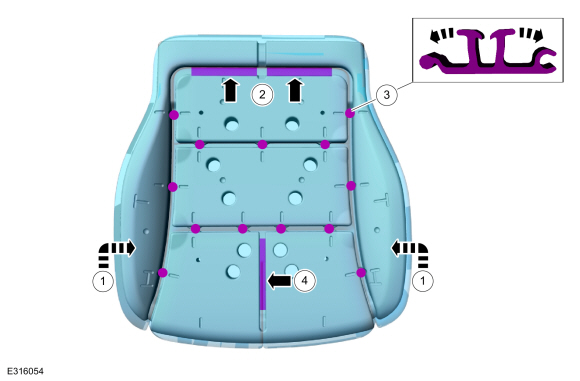

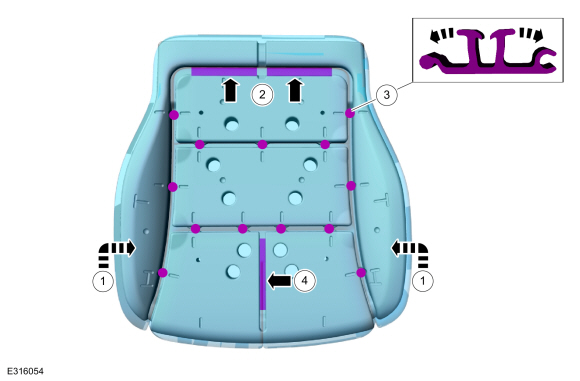

Install the bolts and tighten in sequence shown.

Torque:

Stage 1: 133 lb.in (15 Nm)

Stage 2: 45°

|

- Remove Special Service Tool: 303-507 Timing Peg, Crankshaft TDC.

|

-

NOTE: Measure the backlash and verify that it is within specified range at all of the following 6 positions: 10 degrees, 30 degrees, 100 degrees, 190 degrees, 210 degrees and 280 degrees. It will be necessary to reset the measuring equipment between measurements.

NOTE: The measurement must be taken with the Dial Indicator Gauge with Holding Fixture, a 5-mm Allen wrench and worm clamp set up as shown. Mark the Allen wrench with a file 20 mm (0.79 in) above the driven gear top surface. Make sure the worm clamp and Allen wrench are not touching the balance shaft housing.

-

NOTE: Make sure the worm clamp and Allen wrench are not touching the balance shaft housing.

Install the 5-mm Allen wrench and tighten worm clamp as shown.

-

Mark the Allen wrench with a file 20 mm (0.79 in) above the driven gear top surface.

-

Install the balance shaft preload tool and bolts as shown.

Use Special Service Tool: 303-1688 Preload Tool, Balance Shaft.

-

Install and position the dial indicator gauge with

holding fixture on the Allen wrench 20 mm (0.79 in) as shown.

Use Special Service Tool: 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge.

-

Rotate the crankshaft clockwise and measure the

backlash at all of the following 6 positions: 10 degrees, 30 degrees,

100 degrees, 190 degrees, 210 degrees and 280 degrees.

-

If the backlash exceeds the specified range of 0.040

to 0.140 mm (0.00157 to 0.0055 in), install a new balancer unit and

repeat the procedure.

-

After the special tools are removed, remove the worm clamp and Allen wrench.

Remove Special Service Tool: 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge. , 303-1688 Preload Tool, Balance Shaft.

-

|

-

Lubricate the oil inlet tube O-ring seal with clean engine oil.

Refer to: Specifications (303-01A Engine - 2.0L EcoBoost (177kW/240PS) – MI4, Specifications).

|

-

-

Install the oil inlet tube and the bolts.

Torque: 97 lb.in (11 Nm)

-

Install the oil inlet tube bracket and the bolt.

Torque: 97 lb.in (11 Nm)

-

Install the oil inlet tube-to-bracket bolt.

Torque: 97 lb.in (11 Nm)

-

Install the oil inlet tube and the bolts.

|

-

Lubricate the oil outlet tube O-ring seals with clean engine oil.

Refer to: Specifications (303-01A Engine - 2.0L EcoBoost (177kW/240PS) – MI4, Specifications).

|

-

Install the oil outlet tube and the bolts.

Torque: 97 lb.in (11 Nm)

|

-

Install a new O-ring seal and lubricate with clean engine oil.

Refer to: Specifications (303-01A Engine - 2.0L EcoBoost (177kW/240PS) – MI4, Specifications).

|

-

Install the oil screen and pickup tube and the bolts.

Torque: 97 lb.in (11 Nm)

|

-

NOTICE: If a spark plug is dropped, internal damage may result and the spark plug must be discarded. The use of a damaged spark plug may cause cylinder misfire resulting in engine damage.

Install the spark plugs.

Torque: 106 lb.in (12 Nm)

|

-

Install the special tool and rotate the crankshaft

slowly clockwise until the crankshaft balance weight is up against the

Crankshaft TDC Timing Peg. The engine is now at TDC .

Use Special Service Tool: 303-507 Timing Peg, Crankshaft TDC.

|

-

NOTICE: The Camshaft Alignment Tool is for camshaft alignment only. Using this tool to prevent engine rotation can result in engine damage.

NOTE: The camshaft timing slots are offset. If the Camshaft Alignment Tool cannot be installed, remove the TDC Timing Peg and rotate the crankshaft three-fourths of a revolution clockwise and repeat the previous step of this procedure.

Install Special Service Tool: 303-1685 Alignment Tool, Camshaft.

|

-

Remove the crankshaft pulley bolt.

|

-

Install the oil pan.

Refer to: Oil Pan (303-01A Engine - 2.0L EcoBoost (177kW/240PS) – MI4, Removal and Installation).

Removal and Installation - Timing Chain

Removal and Installation - Timing Chain

Removal

NOTICE:

Do not loosen or remove the crankshaft pulley bolt without

first installing the special tools as instructed in this procedure. The

crankshaft pulley and the crankshaft timing sprocket are not keyed to

the crankshaft...

Other information:

Lincoln Corsair 2020-2025 Service Manual: Removal and Installation - Accessory Drive Belt Tensioner

Materials Name Specification Motorcraft® Silicone Brake Caliper Grease and Dielectric CompoundXG-3-A ESA-M1C200-AESE-M1C171-A Removal NOTICE: Under no circumstances should the accessory drive belt, tensioner or pulleys be lubricated as potential damage to the belt material and tensioner damping mechanism will occur...

Lincoln Corsair 2020-2025 Service Manual: Description and Operation - B Clutch

B Clutch Exploded View Item Description 1 Snap ring 2 B (4, 6, R) clutch apply plate 3 B (4, 6, R) clutch piston seals 4 B (4, 6, R) clutch pistons 5 B (4, 6, R) clutch piston return spring 6 B (4, 6, R) clutch fiber plates 7 B (4, 6, R) clutch steel plates ..

Categories

- Manuals Home

- 1st Generation Lincoln Corsair Owners Manual

- 1st Generation Lincoln Corsair Service Manual

- Technical Specifications

- Refueling - Gasoline

- Child Safety Locks

- New on site

- Most important about car

Autowipers (IF EQUIPPED)

Wet or winter driving conditions with ice, snow or salty road mist can cause inconsistent and unexpected wiping or smearing.